Driving

Metal Casting

towards the 21st century

“Digital Casting Process for Industrial

Volume Production of Metal Alloys”

Previous

Next

TRADITIONAL CASTING IS

STRUGGLING WITH TODAY'S NEEDS

“Labor Shortage | Short Product Lifecycle | Faster Delivery | Greater Product Variability”

•

Labor Shortage: Skills, Retention, Availability

•

Supply Chain Disruptions: Parts Availability, Cost, Time to Market, Control

•

Waste: In-Process, Part and Mold & Energy

•

Tooling: Cost, Availability, Time to Market, Utilization

•

Difficulties Meeting Industry 4.0 Standards

•

Environmental & Safety Concerns

•

Design & Process Limitations

•

New Capabilities – Controlling Alloy Structure and performance, Better Part Design

DIGITAL CASTING:

New Technology, Process & System for Digital Casting, Volume Manufacturing of Metal Alloys

Today vs. Months

- Single process from R&D 🡺 Volume production

- One ton per day per systems

- Saving 6-18 weeks of Tooling time (no Tooling needed)

- Multi part production on same build-table (same Alloy family)

Lower Costs

- Merge parts into one

up to 50% cost reduction

- No tooling =

15-20% cost reduction

- Save up to 70% in

raw material requirements

- Reduce up to 50% of energy consumption

Productivity

- Automated process, less exposure to workforce fluctuations and skill-set

- Industry 4.0 standards

- Enhanced safety

- Enhanced process control

- Merge parts into one

- Using customer alloy (solid metal, no powder)

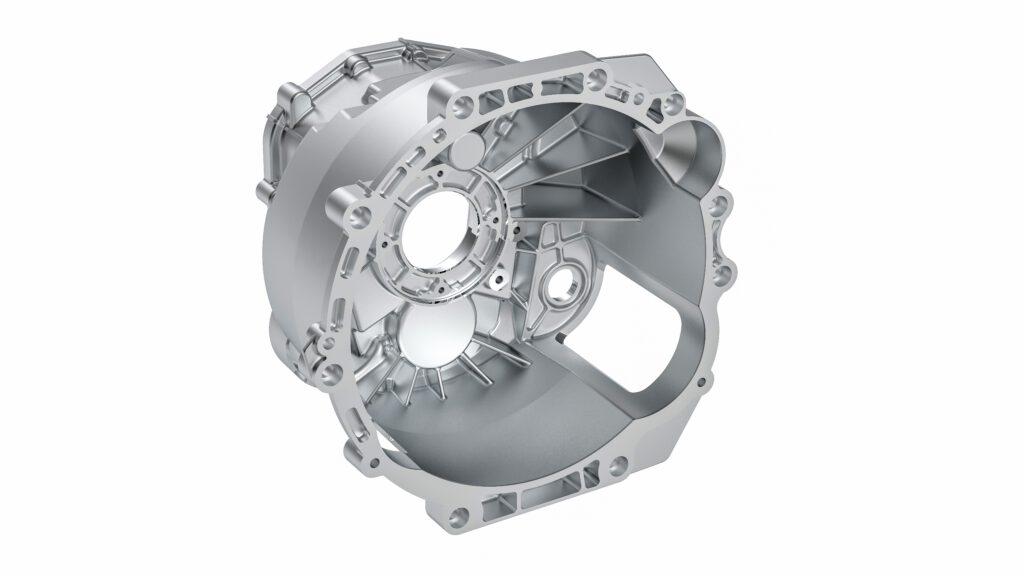

- Unleash design capabilities

- Minimizing effort & time of Design for Manufacturing

New Capabilities

- Multi alloys (same family) in same part

- Full alloy thermal arrest (solidification ) control

- 1mm per 1 meter dimensional accuracy

- Steel casting simplified

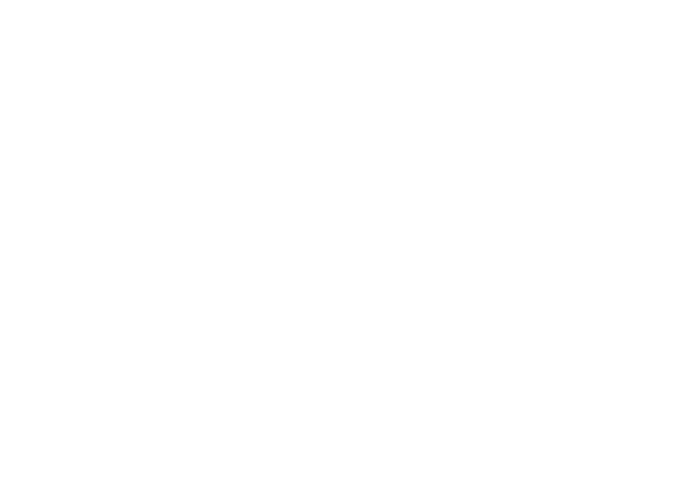

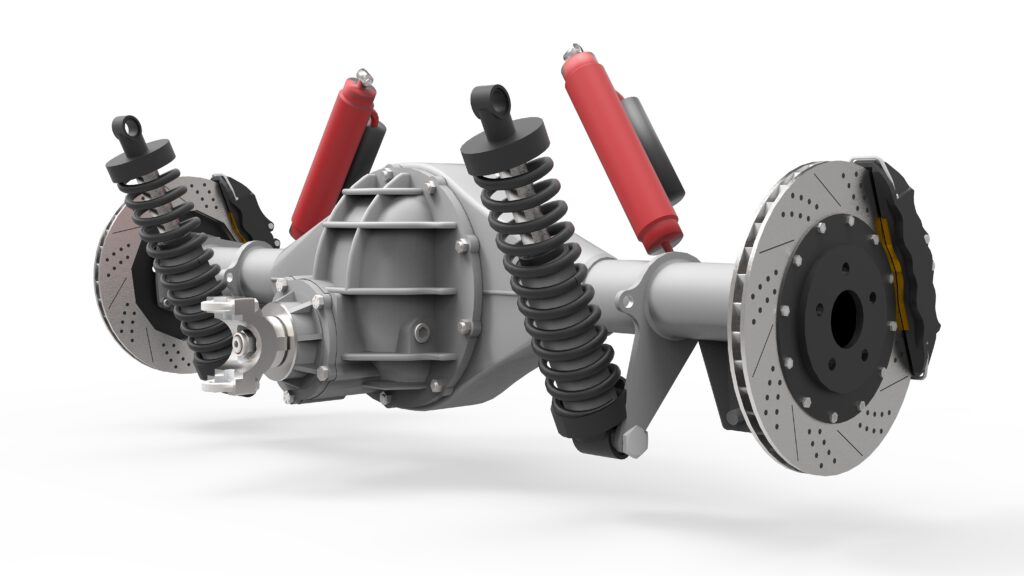

Chassis & Structural Parts

Vehicles | Trucks | Trains

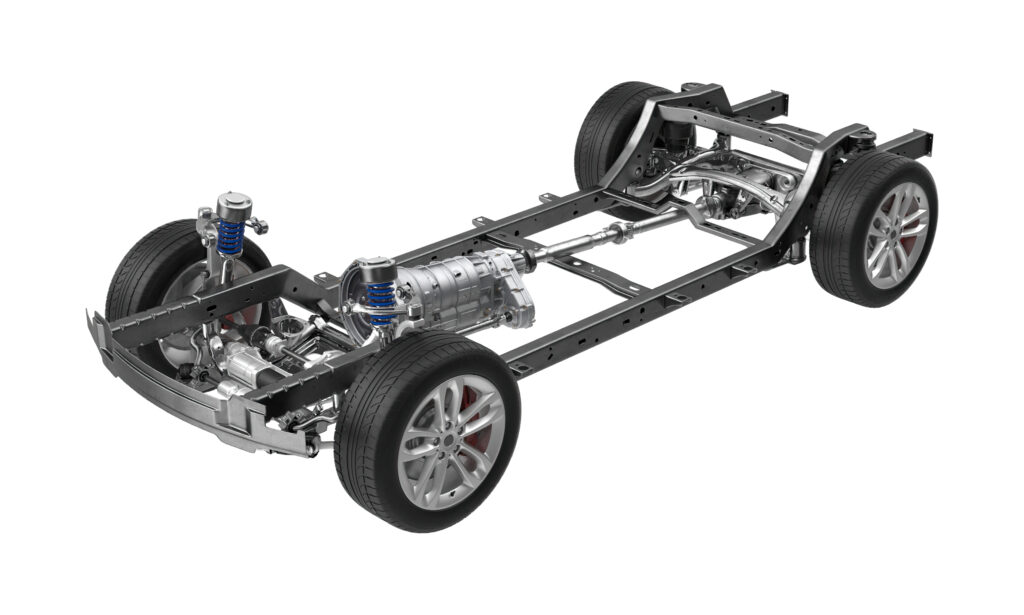

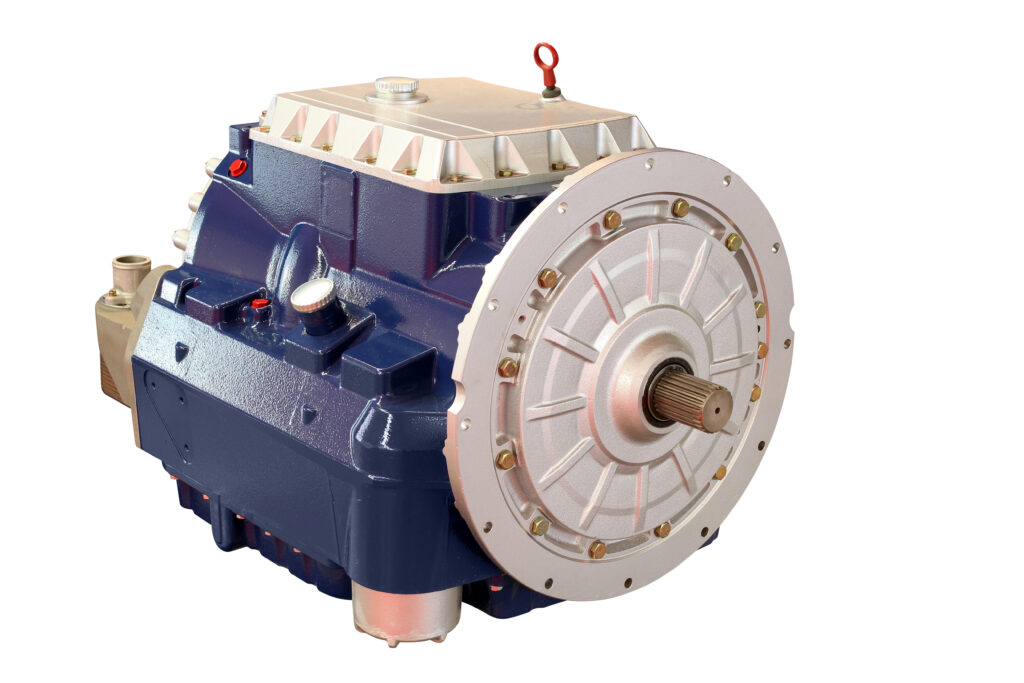

Power-Train & Engine Assemblies

Engine | Axles | Gears

Industrial & Tooling

Robotics | Heavy Duty | Tooling